INDUCTION EXPERTS SINCE 1969

Personalized technology solutions to serve the world of the steel industry and metallurgy

INDUCTION EXPERTS SINCE 1969

Personalized technology solutions to serve the world of the steel industry and metallurgy

Our mission

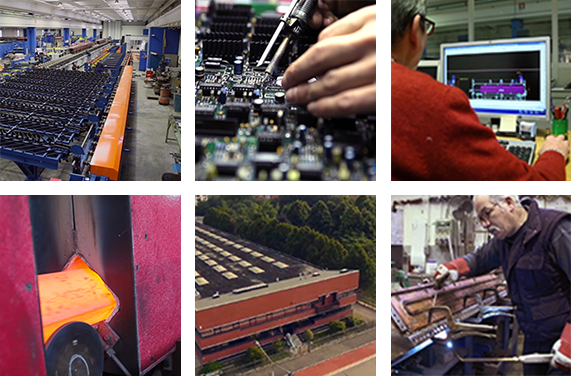

Since 1968 we want to be a worldwide reference point in the creation of Induction Heating Equipment for steel and hot forging companies. We work all over the world collaborating with big industrial groups, developing projects that combine efficiency, sustainability and technological innovation. We assist customers in all phases, from the design to after sales service, providing competence and rapidity of service worldwide. Research and development, attention to the market and a highly specialized staff are the strength points that guide us always to the future.

ELIND Spa

Headquarters:

- Viale delle Industrie 17

- 10078 Venaria Reale (TO)

Registered Office:

- Via Volontari della Libertà 1

- 22036 Erba (CO)

- PHONE :

- FAX: +39 011-95.72.502